What is Stone Veneer Made Of?

Share

In the realm of architectural aesthetics, there exists a material that seamlessly blends the allure of natural stone with the versatility of modern manufacturing processes: manufactured stone veneer, a marvel that has revolutionized the way we approach interior and exterior design. But what exactly is it made of? Let’s embark on a journey to uncover the secrets behind this innovative construction material.

Originally posted May 6, 2024, updated February 11, 2026.

The genesis of manufactured stone veneer

Manufactured stone veneer, often referred to as faux or artificial stone, traces its origins back to the mid-20th century when the need arose for a cost-effective alternative to natural stone. Crafted to mimic the appearance of various types of stone, including limestone, ledgestone, and even brick, this ingenious material combines the aesthetic appeal of natural stone with the advantages of modern manufacturing techniques.

What goes into the mix?

So, what precisely constitutes the makeup of manufactured stone veneer? While formulations may vary among manufacturers, the primary components typically include:

1. Portland cement: at the core of manufactured stone veneer lies Portland cement, a versatile binding agent renowned for its strength and durability. This cement serves as the foundation, providing stability and structural integrity to the finished product.

2. Aggregates: to impart texture and enhance authenticity, various aggregates such as crushed limestone, quartz, or silica sand are incorporated into the mixture. These aggregates contribute to the stone-like appearance and tactile quality of the veneer.

3. Iron oxide pigments: the vibrant hues and intricate patterns characteristic of natural stone are replicated through the use of iron oxide pigments. By meticulously blending pigments into the mix, manufacturers achieve an extensive spectrum of colors, ranging from earthy browns to rustic reds.

4. Chemical additives: to enhance workability, improve bonding, and promote water resistance, manufacturers may introduce chemical additives into the formulation. These additives play a crucial role in refining the properties of the veneer, ensuring optimal performance in diverse environmental conditions.

The manufacturing process

The production of manufactured stone veneer is a meticulous process that combines artistry with cutting-edge technology. Here’s a glimpse into the manufacturing journey:

1. Mixing: the process begins with the precise blending of Portland cement, aggregates, pigments, and additives in predetermined proportions. This meticulous mixing stage lays the foundation for the veneer’s aesthetic and structural characteristics.

2. Molding: once the mixture achieves the desired consistency, it is poured into molds intricately crafted to emulate the texture and shape of natural stone. These molds impart intricate details, ensuring that each piece of veneer bears a striking resemblance to its natural counterpart.

3. Curing: after molding, the veneer undergoes a curing process to strengthen its molecular structure and enhance durability. Depending on the specific formulation, curing may occur through air drying or within controlled curing chambers, where optimal conditions are maintained to facilitate the curing process.

4. Finishing touches: upon completion of the curing process, the manufactured stone veneer undergoes meticulous finishing touches, including trimming, shaping, and surface treatments. These final steps refine the appearance and texture of the veneer, resulting in a product that exudes authenticity and elegance.

The versatility and benefits of manufactured stone veneer

Manufactured stone veneer offers a myriad of benefits that transcend its aesthetic appeal:

1. Cost-effectiveness: compared to natural stone, manufactured stone veneer is significantly more affordable, making it an attractive option for budget-conscious projects.

2. Lightweight construction: its lightweight nature facilitates ease of installation, reducing labor costs and logistical challenges.

3. Durability: engineered for longevity, manufactured stone veneer exhibits exceptional resistance to moisture, fading, and wear, ensuring enduring beauty for years to come.

4. Design flexibility: with an extensive array of colors, textures, and patterns to choose from, designers enjoy unparalleled creative freedom to bring their visions to life.

Frequently asked questions

1. What materials are used to make manufactured stone veneer? Manufactured stone veneer is typically composed of Portland cement, aggregates (such as crushed limestone or quartz), iron oxide pigments, and chemical additives. These ingredients are carefully blended, molded, cured, and finished to replicate the texture, color, and appearance of natural stone.

2. How is manufactured stone veneer made? The manufacturing process involves mixing cement, aggregates, pigments, and additives, pouring the mixture into molds that replicate natural stone shapes, curing the pieces for strength and durability, and applying finishing touches such as trimming and surface treatments to enhance authenticity.

3. Is manufactured stone veneer strong and long-lasting? Yes. Manufactured stone veneer is engineered for long-lasting performance. It is resistant to moisture, fading, cracking, and general wear, making it suitable for both interior and exterior applications while maintaining its aesthetic appeal over time.

4. Can manufactured stone veneer be used indoors and outdoors? Absolutely. Its lightweight yet durable composition makes manufactured stone veneer versatile for interior feature walls, fireplaces, and accent areas, as well as exterior facades, outdoor kitchens, and landscaping features.

5. How does manufactured stone veneer compare to natural stone? Manufactured stone veneer offers the look and texture of natural stone at a fraction of the weight and cost. While natural stone is quarried and heavy, manufactured veneer is easier to install, more versatile in design, and provides similar durability for most residential and commercial applications.

6. What are the benefits of choosing manufactured stone veneer? Manufactured stone veneer is cost-effective, lightweight, durable, and highly customizable. With a wide range of colors, textures, and patterns, it allows homeowners and designers to achieve the aesthetic of real stone without the expense, labor, or structural considerations of full-depth stone.

What is stone veneer made of?

Manufactured stone veneer stands as a testament to the ingenuity and creativity inherent in modern construction materials. By seamlessly blending advanced manufacturing techniques with the timeless allure of natural stone, this innovative material has redefined the possibilities of architectural design. As we continue to push the boundaries of innovation, one thing remains certain, manufactured stone veneer will continue to shape the landscapes of our built environment, one exquisite facade at a time.

You may also like

Why is stone veneer made to order? Benefits and process explained.

Transform your home's interior with stone veneer: Ideas, tips, and benefits.

Is stone veneer good for exteriors? Benefits, durability, and design tips.

What's next?

Ready to transform your space? Shop now or order a sample to experience the quality and texture firsthand!

Have a question?

Please see our full terms of service or check out our frequently asked questions.

For general information and questions please call: (864) 882-8960 Mon. - Fri. 8am - 5pm (EST) or email: info@mountainviewstone.net we are more than happy to help you.

Or you can submit your questions via our contact us page.

We look forward to working with you on your upcoming project.

The Mountain View Stone Team

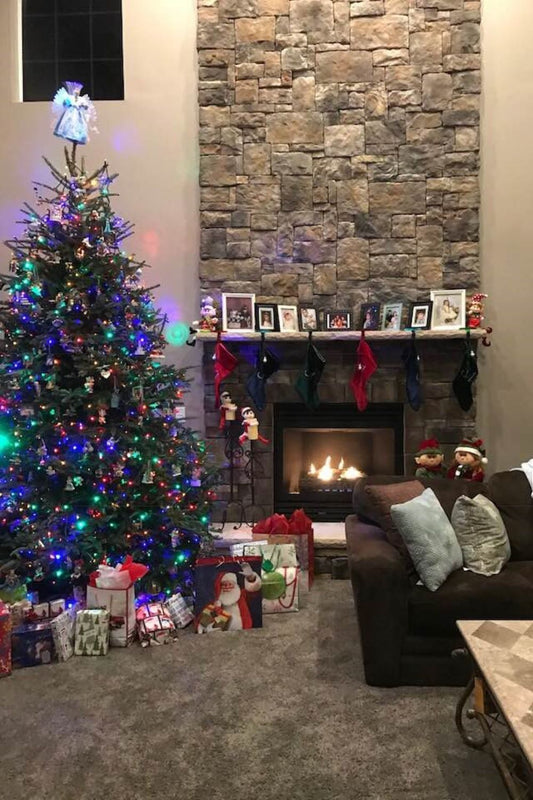

Pictured is ledge stone mossy creek.